Factory Outlets Aircraft Thermal Insulation - Microporous Insulation Board – MINYE

Factory Outlets Aircraft Thermal Insulation - Microporous Insulation Board – MINYE Detail:

Product Description

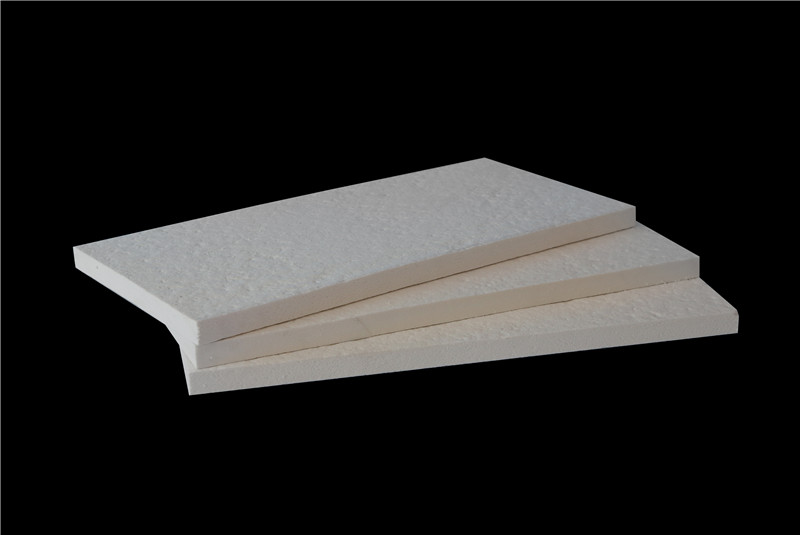

Microporous board is made with special technology using various raw materials, the thermal conductivity is lower than stationary air under atmospheric pressure, only 1/4 to 1/10 than ceramic fiber insulation material, it is the best lowest thermal conductivity solid material. In some high temp equipment which requiring space and weight, microporous board is the best, sometimes the only option. The birth of this materials has promoted related high temp equipment designing innovation.

Typical Features

Super low thermal conductivity and thermal loss

Low heat storage

Excellent thermal stability

Environment friendly

Easy cutting and processing

Long service life

Typical Application

Iron & Steel ( Tundish, ladel, torpedo ladel)

Petrochemical (Pyrolyzer, Hydrogen Transform Furnace, reformer furnace, heating furnace)

Glass (Float glass furnace, glass tempering furnace, bending furnace)

Heat treatment: electric furnace, car-heater, Annealing furnace, tempering furnace etc.

Pipe insulation

Ceramic industry

Power Generation

Domestic appliance

Aerospace

Shipping

mine rescue capsule

Typical product properties

| Microporous Board Typical Product Properties | ||

| Product Name | Microporous Board | |

| Product Code | MYNMB-1000 | |

| Microporous Rate | 90% | |

| Permanent Linear Shrinkage(800℃,12h) | <3% | |

| Nominal Density(kg/m3) | 280kg/m3±10% | |

| Thermal Conductivity(W/m·k) | 200℃ | <0.022 |

| 400℃ | <0.025 | |

| 600℃ | <0.028 | |

| 800℃ | <0.034 | |

| Availability: Thickness: 5mm~50mm | ||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||

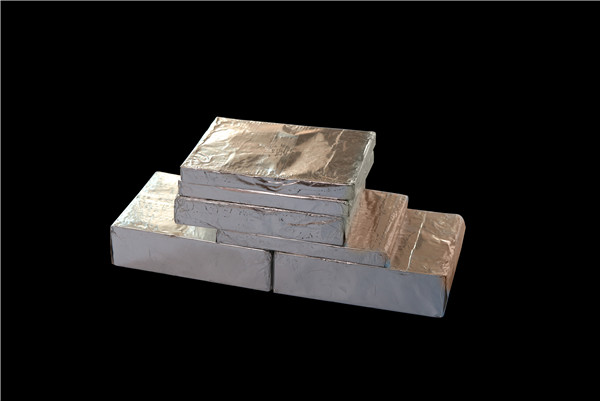

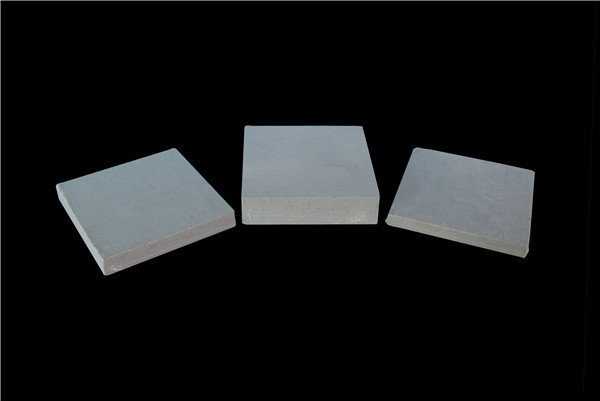

Product detail pictures:

Related Product Guide:

To create more value for customers is our business philosophy; customer growing is our working chase for Factory Outlets Aircraft Thermal Insulation - Microporous Insulation Board – MINYE , The product will supply to all over the world, such as: Suriname, Iceland, Borussia Dortmund, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!