Leading Manufacturer for Ceramic Gaskets - High Temp Refractory Mortar – MINYE

Leading Manufacturer for Ceramic Gaskets - High Temp Refractory Mortar – MINYE Detail:

Product Description

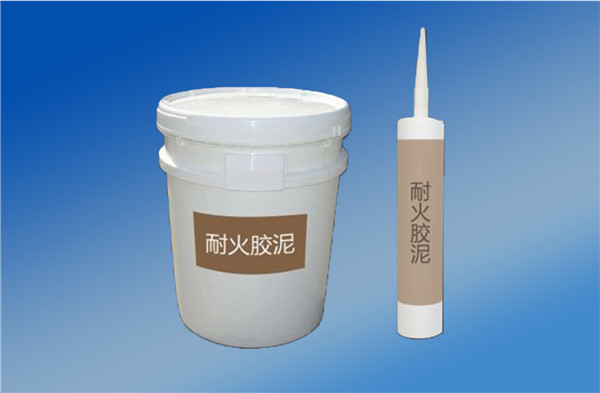

The refractory mortar is a new type of inorganic binding material, made of powder which is of the same quality as the brick installed, inorganic binder and admixture.

It is divided into two types, namely, the air-setting and heat-setting types. It consists of 1400, 1600 and 1750 three classes, each of which is divided into light weight and heavy weight types.

Refractory mortar should be applied as per the brick type.

Typical Features

excellent integration

good porosity; erosion-resistance; long service life

high refractoriness under load

easy installation

high binding strength

high purity

Typical Application

lining for various kinds of kiln

binding refractory fiber blanket and board

Typical product properties

|

Refractory Mortar Product Properties |

||||

| Product Code | MYJN-1400 | MYJN-1600 | MYJN-1750 | |

| Classification Temperature (℃) | 1400 | 1600 | 1750 | |

| Density (g/cm³) | 1700 | 1900 | 2000 | |

| Rupter strength(Mpa) (After drying from 110℃) | 3.1 | 3.5 | 3.7 | |

| Permanent linear thrinkage (%) (After drying from 110℃) | 3 | 2.5 | 2.2 | |

| Refractory degree (℃) | ≥1760 | ≥1790 | ≥1790 | |

| Chemical composition (%) | Al2O3 | 35 | 43 | 55 |

| Fe2O3 | 1.3 | 1.2 | 0.9 | |

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||||

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate purchaser support, our experienced employees members are usually available to discuss your specifications and be certain full shopper satisfaction for Leading Manufacturer for Ceramic Gaskets - High Temp Refractory Mortar – MINYE , The product will supply to all over the world, such as: Qatar, Naples, New Orleans, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

Write your message here and send it to us