Well-designed Ceramic Paper Uses - Mullite light-weight insulation bricks – MINYE

Well-designed Ceramic Paper Uses - Mullite light-weight insulation bricks – MINYE Detail:

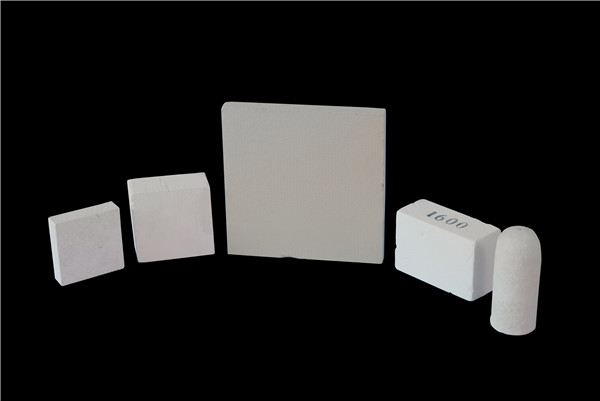

Product Description

The light weight mullite bricks contains high porosity, which can save more heat and therefore reduces the cost of fuel. Meanwhile the light weight means less heat storage capacity, so less time is required when the kiln is heated or cooled. Faster periodic operation is workable.

It can be applied at the temperature range from 900 to 1600 ℃.

It is mainly used as kiln lining in high temperature(less than 1700 ℃) kilns of ceramics, petrochemical, metallurgy and machinery.

Typical Features

Low thermal conductivity, low heat capacity, low impurity content

High strength, excellent thermal shock resistance, erosion resistance

Accurate dimension

Typical Application

Ceramics roller kiln and shuttle kiln: standard brick, roller passage hole brick, hanger brick,

Metallurgy industry: hot blast furnace; inner lining of foundry kilns

Power industry: power generation and fluidised bed equipment

Electrolytic Aluminium industry: kiln inner lining

Typical product properties

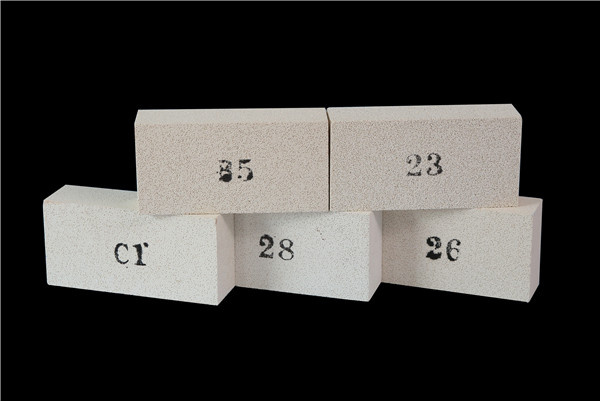

|

Mullite light-weight insulation bricks Product Properties |

||||||

| Product Code | MYJM-23 | MYJM-26 | MYJM-28 | MYJM-30 | MYJM-32 | |

| Classification Temperature (℃) | 1260 | 1400 | 1500 | 1550 | 1600 | |

| Density (g/cm³) | 550 | 800 | 900 | 1000 | 1100 | |

| Permanent linear thrinkage (℃×8h) | 0.3 (1260) | 0.4 (1400) | 0.6 (1500) | 0.6 (1550) | 0.6 (1600) | |

| compressive strength(Mpa) | 1.1 | 1.9 | 2.5 | 2.8 | 3 | |

| Repture strength(Mpa) | 0.8 | 1.2 | 1.4 | 1.6 | 1.8 | |

| Thermal conductivity (W/m.k) (350℃) | 0.15 | 0.26 | 0.33 | 0.38 | 0.43 | |

| Chemical composition (%) | Al2O3 | 40 | 54 | 62 | 74 | 80 |

| Fe2O3 | 1.2 | 0.9 | 0.8 | 0.7 | 0.5 | |

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||||||

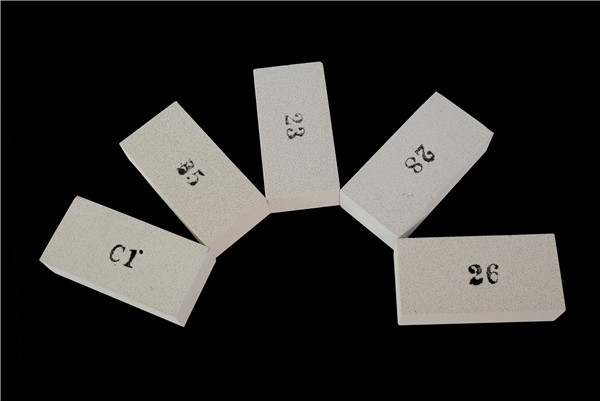

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for Well-designed Ceramic Paper Uses - Mullite light-weight insulation bricks – MINYE , The product will supply to all over the world, such as: Gambia, Greenland, Grenada, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.