Factory wholesale Kitchen Exhaust Duct Insulation Requirements - Microporous Insulation Board – MINYE

Factory wholesale Kitchen Exhaust Duct Insulation Requirements - Microporous Insulation Board – MINYE Detail:

Product Description

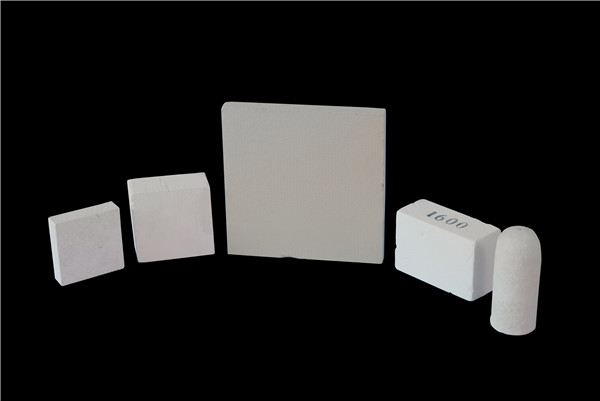

Microporous board is made with special technology using various raw materials, the thermal conductivity is lower than stationary air under atmospheric pressure, only 1/4 to 1/10 than ceramic fiber insulation material, it is the best lowest thermal conductivity solid material. In some high temp equipment which requiring space and weight, microporous board is the best, sometimes the only option. The birth of this materials has promoted related high temp equipment designing innovation.

Typical Features

Super low thermal conductivity and thermal loss

Low heat storage

Excellent thermal stability

Environment friendly

Easy cutting and processing

Long service life

Typical Application

Iron & Steel ( Tundish, ladel, torpedo ladel)

Petrochemical (Pyrolyzer, Hydrogen Transform Furnace, reformer furnace, heating furnace)

Glass (Float glass furnace, glass tempering furnace, bending furnace)

Heat treatment: electric furnace, car-heater, Annealing furnace, tempering furnace etc.

Pipe insulation

Ceramic industry

Power Generation

Domestic appliance

Aerospace

Shipping

mine rescue capsule

Typical product properties

| Microporous Board Typical Product Properties | ||

| Product Name | Microporous Board | |

| Product Code | MYNMB-1000 | |

| Microporous Rate | 90% | |

| Permanent Linear Shrinkage(800℃,12h) | <3% | |

| Nominal Density(kg/m3) | 280kg/m3±10% | |

| Thermal Conductivity(W/m·k) | 200℃ | <0.022 |

| 400℃ | <0.025 | |

| 600℃ | <0.028 | |

| 800℃ | <0.034 | |

| Availability: Thickness: 5mm~50mm | ||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||

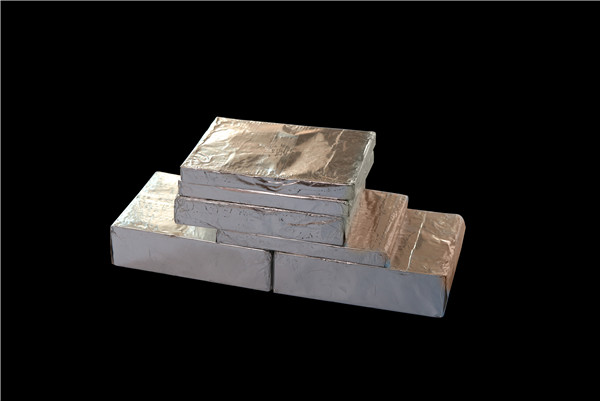

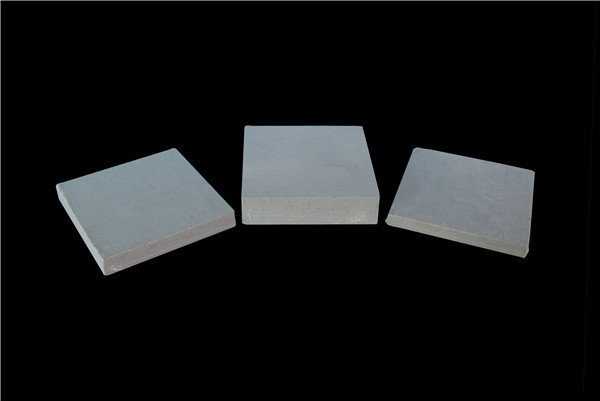

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Factory wholesale Kitchen Exhaust Duct Insulation Requirements - Microporous Insulation Board – MINYE , The product will supply to all over the world, such as: Singapore, Melbourne, Armenia, The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.